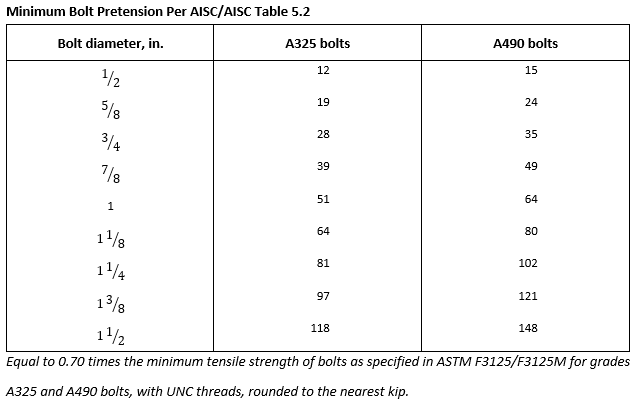

In bearing the resistance of a blind bolt should satisfy the requirements of aisc specification 360 10 clause j3 10 expressions j3 6a or j3 6b as required using the nominal diameter d of the bolt.

Blind bolt spec.

Blind flange datasheets and dimensional information.

It is different than a valve in that the blind is a permanent or long term isolation device.

In combined tension and shear blind bolts should satisfy the following expressions.

The thin wall bolt has a strong shear capacity.

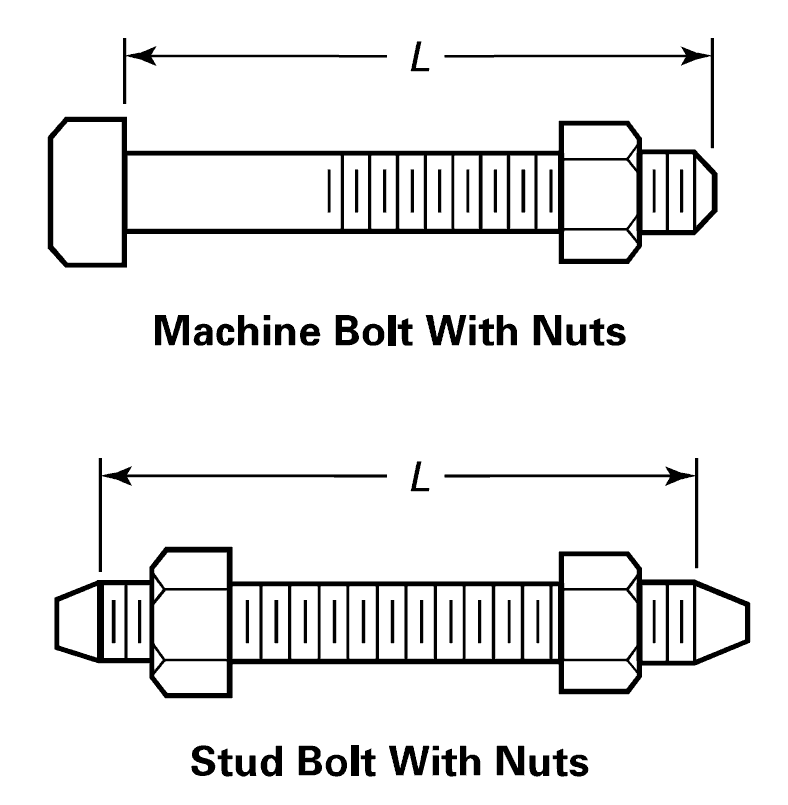

D hole size where required should be the same as the flange bolt hole.

The huck blind bolt system is a service proven high strength blind fastening system which combines important features of structural durability and fabrication convenience with good economics.

Maxibolts are primarily used in structures where higher loads are required.

Special configurations huck part numbers and procurement specifications.

W 5 32 nominal diameter cherry maxibolt blind bolt 219 min.

Wt thickness of the web or tie bar should be 6 mm minimum or equal to thickness t if less than 6 mm.

Blind flange dimensions class 150 to class 2500 outer diameter of body bolt circle bolt hole diameter straightness and alignment of the bolt hole thickness of the blind.

In practice these dimensions have been rounded round off upwards.

Because the blind flange s sole purpose is to contain the pressure of the pipe it and its bolts are stressed more.

Oversize repair parts huck part numbers and procurement specifications.

When used at the end of a pipe vessel or tank it provides an easy open access for further extension of the pipe.

The tw or thin wall bolt was developed to address the need for a blind fixing to be used into lightweight steel sheet or cladding material.

A spectacle blind or spec blind abbreviated as sb is a safety device used to isolate a section of line or piece of equipment when the line or equipment needs to be inspected or removed from service.

No reduction in diameter to allow for the slot is required.

The original 3 part design for general hollow section connections and the larger sized 5 part high clamping force hcf.

After installation a neat low profile head is left with no stud.

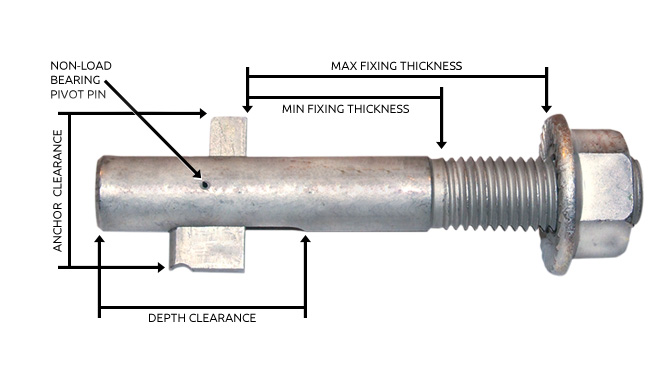

As the bolt head is tightened the cone is pulled up the bolt thread causing the legs of the sleeve to expand until the cone locks the sleeve against the inner wall of the hollow section available in two versions.

Grip with blue anodize on sleeve.

Hollo bolt an expansion bolt for structural hollow sections shs hss with blind connections when you only have access to one side of the connection.